SAN DIEGO, CA, MEXICO, August 11, 2024 /EINPresswire.com/ — Glohab, Inc. is excited to announce the launch of its revolutionary INCABLOCK™ Construction System. This groundbreaking sy...

Lisa Colon on Managing Construction Industry Tariff Impacts

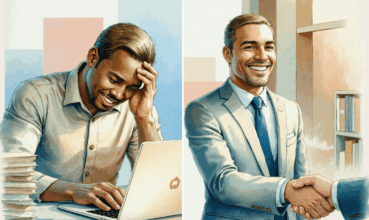

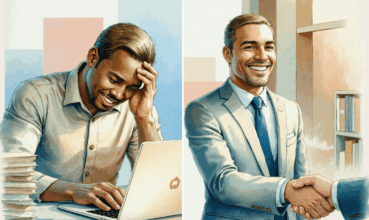

“It’s better to have it in the contract and not need it than not have it at all when you need it,” advises Lisa Colon, Partner at Saul Ewing and a construction law attorney with 25 years of experience who has weathered her share of industry disruptions.

When tariffs affect construction materials like steel and aluminum, the industry faces unique challenges that go beyond simple cost increases. While policy discussions and political debates may dominate headlines, construction professionals need practical strategies to manage these impacts on their projects and businesses.

The Triple Threat: Cost, Supply, and Time

The construction industry faces three interconnected challenges when tariffs on materials are implemented: direct cost increases, supply chain disruptions, and project delays.

“For those projects that are in progress, if they have not already procured the steel… who’s going to bear the cost? Or how are they going to renegotiate with that subcontractor?” Colon questions. “At the end of the day, it’s the contractor that really owes the price to the owner. So if it’s a fixed price contract, who’s going to eat that cost?”

These aren’t theoretical concerns. According to Colon, “If there is a sudden increase in steel and lumber,” developers could see price increases of “three to 5% perhaps reaching up to 10%” on these essential materials, significantly impacting project budgets.

Market Behavior: The Speculative Response

Beyond direct price increases, market behaviors can create additional complications. “When price is volatile, a lot of folks speculate, and so they will buy,” Colon explains, drawing parallels to behaviors seen during COVID-19. “The large contractors who have the ability to buy in bulk and to store may do some of that.”

This speculative purchasing can create artificial shortages and further price volatility—particularly for materials like lumber that can be more easily stockpiled than steel. The result can be supply chain disruptions even more severe than the tariffs themselves would create.

“We may have a run on supply,” Colon warns. When lead times extend unexpectedly, schedules built around typical delivery timeframes can collapse, cascading into costly delays across the entire project.

America’s Material Dependency Challenge

The construction industry’s vulnerability to tariffs stems from America’s position as a net importer of construction materials. “We consume the most in the world of most materials that we import,” Colon notes. “We’re currently not producing enough steel for our needs.”

Canada is the largest supplier of steel and aluminum to the United States, with other major suppliers including Brazil, Mexico, South Korea, and Vietnam for steel. This dependency means the construction industry has limited alternatives when tariffs affect global supply chains.

“The good part of a tariff is supposedly to make the price of importing high enough that we start manufacturing locally,” Colon explains. “The problem is, in the interim, there is a price to be paid by the American consumer.”

Contract Strategies: Who Bears the Burden?

The question of who absorbs these increased costs is primarily determined by contract structure. “It’s very contract dependent,” Colon emphasizes. While most people think of lump sum contracts where contractors absorb overruns, the reality is more nuanced.

“Generally, large projects will have contingency funds, both developer contingency and contractor contingency,” Colon explains. These contingencies can be structured with “escalation clauses” that determine how unexpected increases are shared between parties.

Colon advises that these clauses specify exact formulas: “We can say now the contingency clause kicks in, and the developer will eat 10% and the contractor will pay 5% out of their different contingencies. That’s how you cover that risk.”

Force Majeure: The Legal Safety Net With Limitations

Many industry professionals are reviewing force majeure clauses as potential protection against tariff impacts. These provisions typically excuse delays and sometimes cost increases caused by extraordinary events outside parties’ control.

However, standard force majeure language may not explicitly address tariffs. “Usually force majeure clauses would say acts of God, labor strikes, war, pandemics,” Colon notes. “I don’t know if I’ve seen one with tariffs.”

This represents a critical vulnerability, especially after COVID-19 demonstrated that courts often interpret these clauses narrowly. “Make sure that force majeure clause is specifically identifying tariffs and supply chain using those words,” Colon advises, “because what we saw in COVID is that if the force majeure clause was not specific enough, we’re not going to enforce it.”

The Compounding Effect: Labor Shortages Intensify the Challenge

Adding to these material concerns is the construction industry’s persistent labor shortage, which Colon identifies as an issue since at least 2019. “We’ve had a labor shortage in construction. It’s been like that since I say 2019,” notes Colon, pointing to a skilled trades gap that continues to widen as more workers retire than enter the field.

“Who’s going to feel it are the trades, the small trades feel the labor shortages,” Colon explains. “It’s not the big contractor, because they don’t really self-perform any of the work. The folks that really feel the labor shortage are going to be your roofer, your painter, the small trades that come on the project and do the actual work.”

This labor shortage compounds the challenges posed by material cost increases and supply chain disruptions, creating what Colon describes as a “perfect storm” for certain projects.

Five Strategic Responses for Industry Resilience

Despite the challenges, Colon advises against panic reactions: “Turn the TV off. There’s no reason to panic.” Instead, she recommends focused preparation through these actionable steps:

- Review existing contracts for force majeure provisions and contingency mechanisms that could provide relief

- Update contract templates to specifically address tariffs and supply chain disruptions with clear language

- Build in price contingencies with defined escalation clauses that specify who bears what percentage of increases

- Establish communication protocols between owners, contractors, and subcontractors to quickly address emerging issues

- Consider domestic sourcing alternatives where feasible, even if at a premium, to reduce exposure to tariff volatility

“Just be proactive,” Colon emphasizes. “It’s time to dust off [your contracts] and really take a look at them and see whether or not you’re addressing the issues that could come.”

The Long View: Industry Adaptation

While immediate concerns dominate attention, tariff situations may ultimately accelerate broader industry changes. Increased material costs could drive adoption of alternative building materials, modular construction techniques, and technological solutions that reduce material and labor dependencies.

The construction industry has weathered economic challenges before, and Colon remains cautiously optimistic: “I think there’s going to be an adjustment. Some industries are going to have to become creative in pricing, but I don’t think there’s a need to panic.”

For stakeholders dealing with projects affected by tariffs, this adjustment means scrutinizing contracts, having difficult conversations, and preparing for potential cost increases and delays. For those planning future projects, it means reimagining contract structures and perhaps even building methods to create resilience against an increasingly volatile global trade environment.

The construction professionals who prepare thoroughly now will navigate these challenges most successfully, regardless of which way the political winds blow.

This article was sourced from a live expert interview.

Every month we conduct hundreds of interviews with

active market practitioners - thousands to date.

Similar Articles

Explore similar articles from Our Team of Experts.

The real estate market is seeing a growing preference for conservative, unremarkable investments that deliver steady returns, according to Eric Scheffler, Co-Founder and Managing Partner at ...

Industry veteran highlights how outdated paper documentation puts building safety at risk, advocating for mobile-first emergency response systems. The difference between minor incident and m...

The commercial real estate industry stands at a technological tipping point where network effects are dramatically amplifying the value of digital platforms, according to Steve LaMotte Jr., ...

A veteran Detroit broker says the public often fails to understand the increasingly complex role of real estate professionals, comparing agents to ducks that appear to glide smoothly across ...